Citra Quality Affordable Fast Building Technology

How do we do it?

Citra was founded with the objective of developing green buildings of:

- higher in quality

- lower cost

- fast build

As indicated by the McKinsey Global Institute report on the construction industry in 2017, a holistic approach must be followed to accomplish rethinking from the ground up in an integrated manner the following aspects:

- The building technology

- The production technology

- The information flow

Why is speed a critical factor?

The advantages of higher quality and lower cost are apparent. Speed, however, has two major impacts:

- it increases customer satisfaction if their dream home is ready sooner

- it allows the same working capital to be used more frequently, increasing capital efficiency.

This reduces costs even further and increases the amount of homes built. For example, if a conventional home takes six months to build, while Citra can build it four to six times faster, the same working capital can produce four to six times more homes.

Citra’s approach combines continuous improvement (Kaizen) with dedicated in-house R&D and a strong network to universities and research institutes across the globe.

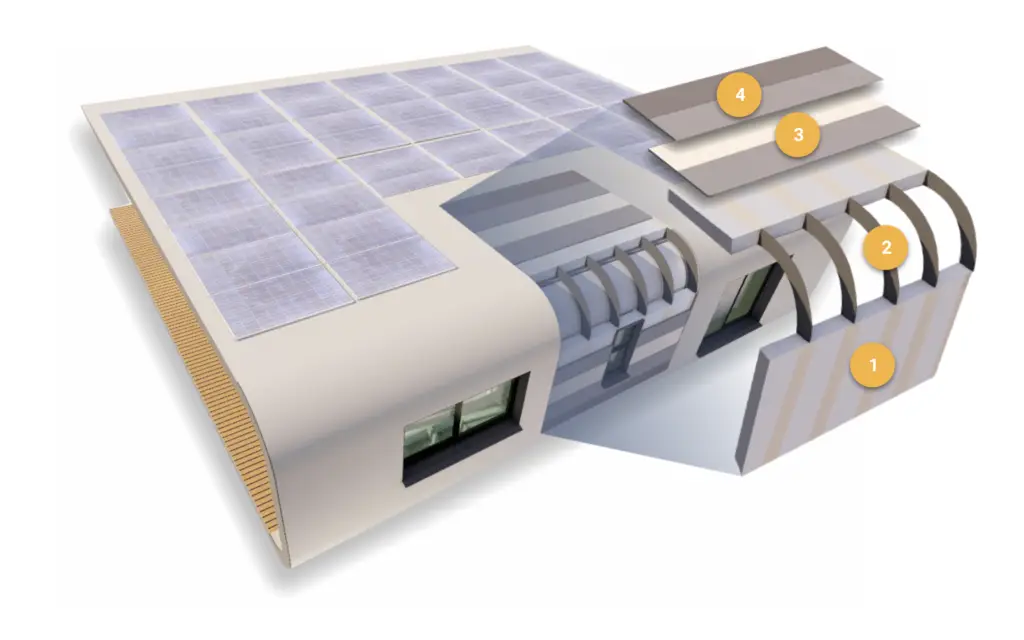

EPS: thermal insulation, recyclable

MgO: structural support, recyclable

Plaster: reinforced

Waterproofing

*pending patent

Redefining Sustainable Construction

Dive deeper into Citra's innovative materials and building techniques.

Benefits of the Citra Building Technology

Reduction of ecological footprint

Grey energy is reduced through the utilization of thermal insulation alongside minimal plaster, meeting structural requirements.

Operational energy is minimized thanks to superior thermal insulation.

Waste is mitigated through extended lifespan, with EPS being recyclable.

Design freedom

EPS and MgO can be cut into any shape, and spray plaster application is fully flexible. This supports designs from ultra-low-cost tiny homes to fancy spacious villas, and allows Citra to develop a unique design language.

Superior quality

In comparison to a conventional timber-frame home in the United States, a Citra home is more durable, does not rot, is highly resistant to hurricanes, and has better acoustic and thermal insulation. Compared to a traditional brick-and-mortar home, Citra provides superior thermal insulation, which helps avoid mold and cold spots.

Lower costs

Using current production technology, a Citra home built without robots is 10-15% less expensive than a comparable conventional home. Once plaster robots and mobile EPS-factories are used, costs are expected to decrease by another 15% or more. Homeowners benefit from lower heating and cooling costs, lower maintenance costs, and an extended lifespan.

Faster construction

A full home can be constructed with EPS-MgO panels in a single day. Spray-plastering requires 2-3 working days, spread over two weeks. Citra currently builds homes in 6-8 weeks, and aims to reduce this to one month.

Mobile automation and robots

Robots and mobile automation will play a major role in the future of construction, improving efficiency, reducing costs and material waste, and increasing quality. Citra has already begun developing a mobile EPS factory on trucks and is collaborating with industry partners on plaster robots. These technologies will allow Citra to build high-quality, cost-effective structures in a fraction of the time it takes traditional methods.

More space to live

In dense urban areas of Europe and North America, where thermal insulation is essential but living space is at a premium, the Citra technology can make walls thinner by 10-12 centimeters, resulting in a 3-5 percent increase in living space.

Production Technology

Current

Citra currently employs cutting-edge software for design and nesting to minimize production waste. EPS suppliers utilize CNC hot wire to cut EPS sheets from EPS blocks, while Citra employs CNC machines to cut MgO ribs from large MgO panels. These components are then assembled in the Citra factory into larger panels, typically 1.8 by 2.5 meters, that include rebars and installed services as needed, but are not yet plastered.

Panels are transported to the construction site, where they are erected. Service installations are completed, depth gauges and corner beads are put in place, slab and roof rebars are spliced, and a thin layer of bonding plaster is sprayed onto the panels. Later, the main plaster layer is sprayed and finished.

The next five years

Looking ahead, Citra plans to implement several advancements. One major focus is the introduction of plaster robots, along with the construction of mobile EPS-factories, which will be integral to mobile Citra Factories. While the mobile EPS-factory poses fewer technical challenges, its economic viability hinges on building a minimum number of homes per year.

In addition to these developments, Citra is exploring various smaller ongoing projects. These include incorporating more prefabricated components in interior finishes, fast foundation concepts, integrated photovoltaic systems, and other energy-related improvements. They also aim to optimize practical work processes.

Throughout these endeavors, Citra’s ultimate goal remains consistent: to achieve better, cheaper, and faster construction outcomes.

Software

Throughout Citra, state of the art tools and data integration is considered a cornerstone. This applies to all key areas, from design to production to sales, from backoffice to construction site, from administration to engineering and optimization. While all key areas are already well supported, and a central Data Warehouse brings much of the data together, Citra aims to push the integration further, so that efficiency and speed are further improved.